NDT tools for power plants play a critical role in ensuring reliable, safe, and efficient operations without unexpected shutdowns. In Combined Cycle Power Plants (CCPPs), inspections are often delayed until planned outages — but that’s no longer necessary with smart NDT solutions.

From inspecting HRSG welds to verifying turbine casing integrity and checking pipe wall thickness, NDT tools help detect faults without halting operations.At ProcureEaze, we help U.S. power plants source NDT equipment, accessories, and replacements globally — from ultrasonic flaw detectors to thermal imagers, phased array units, and MPI kits.

1. Understand Why NDT Is Critical to CCPP Operations

Leaks, fatigue cracks, and corrosion don’t just happen during outages — they evolve over time.

NDT tools help identify:

- Surface and sub-surface weld defects

- Corrosion under insulation (CUI)

- Wall thinning in HRSG tubes

- Heat-affected zone (HAZ) cracks

- Turbine casing microfractures

Early detection allows maintenance teams to act during planned windows, reducing forced outages and repair costs.

2. Know the Core NDT Methods Used in Power Plants

Each plant area demands different tools. For example:

- Visual Testing (VT):

Weld seams, flange faces, fasteners (pre-outage walkdowns) - Ultrasonic Testing (UT):

Detects internal cracks, thinning in tubes and drums - Radiographic Testing (RT):

High-precision weld quality verification (requires access control) - Magnetic Particle Inspection (MPI):

Surface crack detection on ferromagnetic components (e.g., shafts, bolts) - Dye Penetrant Testing (PT):

Small cracks on non-ferrous components (e.g., turbine blades) - Infrared Thermography (IR):

Hot spot and insulation loss detection across ductwork and casings

ProcureEaze helps source kits and calibration blocks matched to each method.

Investing in high-quality NDT tools for power plants reduces inspection times and maintenance costs.

3. Source the Right Tools for the Right System

Your HRSG weld inspection team doesn’t need the same tools as your rotating equipment specialist.

Choosing the right NDT tools for power plants can greatly reduce inspection time and improve defect detection accuracy.

We help U.S. plants source equipment such as:

- Portable ultrasonic flaw detectors

- Magnetic yokes and coils

- Penetrant/dye kits with cleaners and developers

- Phased array probes with angle beam wedges

- Radiographic film, digital plates, and readers

- Thermal cameras for predictive maintenance

All tools come with material certificates, user calibration guides, and compatible consumables.

With smart sourcing and training, NDT tools for power plants can significantly extend system life and operational safety.

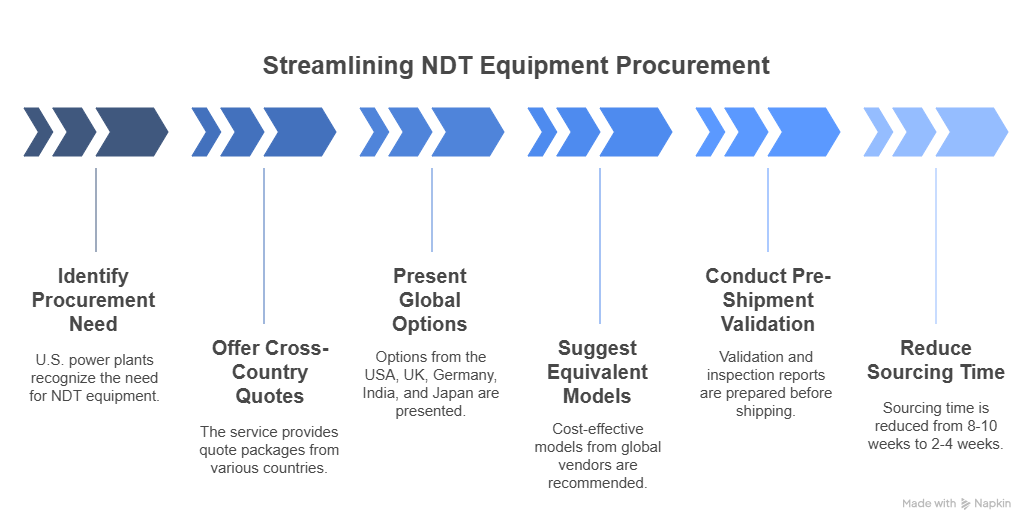

4. Streamline Procurement with Global NDT Sourcing

U.S. power plants often overpay for NDT gear due to limited local inventory or delayed response from OEMs.

We support you with:

- Cross-country quote packages for each NDT kit

- Options from the USA, UK, Germany, India, and Japan

- Equivalent models from cost-effective global vendors

- Pre-shipment validation and inspection reports

Need a certified MPI yoke or ASME-compliant UT unit next week? We help reduce sourcing time from 8–10 weeks to 2–4 weeks.

5. Prepare for Outages with Pre-Kitted Inspection Gear

Most inspection delays happen due to missing:

- Probe cables

- Spare batteries

- Developer sprays

- Carrier oils

- Certified calibration blocks

At ProcureEaze, we help build pre-packed inspection kits for:

- HRSG tube inspections

- Steam turbine casing integrity checks

- Condenser leak testing

- Pipe weld and flange verification

You don’t need 5 vendors — you need one smart sourcing plan.

6. Train and Standardize for Better Inspection Accuracy

Buying tools is easy. Getting accurate readings isn’t.

We help connect plants with suppliers that offer:

- Tool-specific training modules (online or in-person)

- Calibration toolkits and block sets

- Replacement parts and probes

- SOP documentation for audit trail compliance

Better sourcing leads to better inspections — and fewer reworks or insurance flags.

Final Word: Inspect Smarter, Not Just Harder

Non-Destructive Testing doesn’t just improve safety — it saves money, time, and reputation. In a Combined Cycle Power Plant, missed defects can become million-dollar mistakes. Investing in quality NDT tools for power plants ensures better inspection, safety, and long-term cost savings.

Let ProcureEaze help you find, compare, and source the best NDT equipment for your plant — without the delays, markups, or guesswork.

Contact us today to find the best NDT tools for power plants at competitive prices!

Contact Us

Email: cs@procureeaze.com

Phone / WhatsApp: +1 347 288 9678

Website: www.procureeaze.com

Address: 624 5th Ave, New Hyde Park, NY 11040, USA

Parent Company: Impro Solutions UK Limited

Company Reg: 11768437 | VAT: 318 763 677

Disclaimer: This content is provided for industrial awareness and educational reference. All brand names and technical specifications belong to their respective owners. Please contact us for adjustments or official authorization.