Procurement Delays of HRSG Spare Parts Disrupt More Than Just Power Output

Every delay in sourcing HRSG spare parts increases operational risks and costs. Emergency repairs drive up fuel usage, labour costs, and penalties. Inefficient procurement weakens plant stability and profitability, making proactive sourcing essential.

Inefficient Procurement Increases Fuel Consumption

When HRSG components degrade, turbines compensate by burning more fuel. This raises gas consumption, emissions, and operational expenses. Power plants face unnecessary financial losses and energy inefficiencies without timely part replacements.

Emergency Sourcing Leads to Price Hikes and Delays

Urgent procurement results in inflated costs due to expedited shipping and last-minute vendor markups. Large HRSG components, like expansion joints and safety valves, require specialised logistics, further increasing expenses and disrupting supply chains.

Unplanned Maintenance Overburdens Workforce and Budget

Without available spare parts, maintenance teams operate reactively, diverting their focus from optimization. Overtime costs increase, reducing workforce efficiency and straining plant resources. Productivity also suffers as teams scramble for last-minute procurement solutions.

Failure to Meet Energy Contracts Results in Revenue Losses

Power purchase agreements demand uninterrupted energy supply. HRSG maintenance delays lead to missed production targets, financial penalties, and lost contracts. Procurement inefficiencies put plant reliability and future business opportunities at risk.

How to Prevent HRSG Spare Parts Procurement Delays

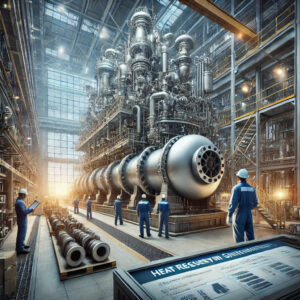

Securing critical HRSG spare parts in advance reduces risks and operating expenses. HRSG tube bundles improve heat transfer, expansion joints prevent structural failures, safety valves regulate pressure, and diverter dampers optimize steam flow.

Comparing multiple supplier quotes ensures cost-effective procurement. Securing at least five vendor options prevents price gouging, while cross-border sourcing provides access to high-quality, competitively priced HRSG parts.

Streamlining procurement eliminates supply chain bottlenecks. Establishing pre-approved vendor agreements guarantees faster access to critical HRSG components, while automated RFQ processes reduce delays and improve supplier response times.

Contact us at cs@procureeaze.com to streamline your supply chain and secure essential HRSG components today. CLICK HERE for more to know. Our own sourcing company HERE