HRSG Parts Procurement is a major concern for power plant operators managing Combined Cycle Power Plants (CCPPs). They have one job: maintain peak uptime while ensuring safety and cost-efficiency. But when it comes to sourcing HRSG Parts Procurement, delays and procurement obstacles are not just frustrating — they’re operational threats.

This blog uncovers the most common challenges power plant operators face and how sourcing support from a global partner like ProcureEaze can turn these headaches into competitive advantages.

What Makes HRSG Parts So Critical?

HRSG systems are at the heart of every CCPP, recovering exhaust heat from the gas turbine and converting it into steam to drive the steam turbine.

But HRSGs are complex, high-maintenance systems made up of dozens of specialized components, such as:

- Tubes, headers, and coils

- Duct burners and diffusers

- Gaskets, seals, and expansion joints

- Valves, dampers, and silencers

- Pressure parts, insulation, and fasteners

Sourcing these items — especially during scheduled outages or emergency shutdowns — requires precision, speed, and supply chain reliability.

7 Major Procurement Challenges Operators Face with HRSG Parts

1. Long Lead Times from OEMs

→ OEMs often quote 8–16 weeks or more for critical HRSG parts. When your maintenance window is tight, waiting is not an option.

2. Outdated or Obsolete Components

→ Some HRSG models are decades old. OEMs may no longer support specific components, forcing operators to find equivalents or redesign systems.

3. Inconsistent Technical Documentation

→ Operators often lack updated drawings or BOMs, making it harder to generate RFQs or find part alternatives.

4. Overpriced Local Suppliers

→ Domestic suppliers may mark up parts significantly, especially during high-demand periods.

5. No Multi-Country Price Comparison

→ Most plants don’t have the time or network to compare prices across the UK, EU, India, and the USA.

6. Delayed Response to RFQs

→ Some suppliers take days or even weeks to respond, slowing down the entire outage plan.7. Limited In-House Procurement Bandwidth

→ Operations and maintenance teams often lack the manpower to chase quotes, validate specs, and manage logistics.

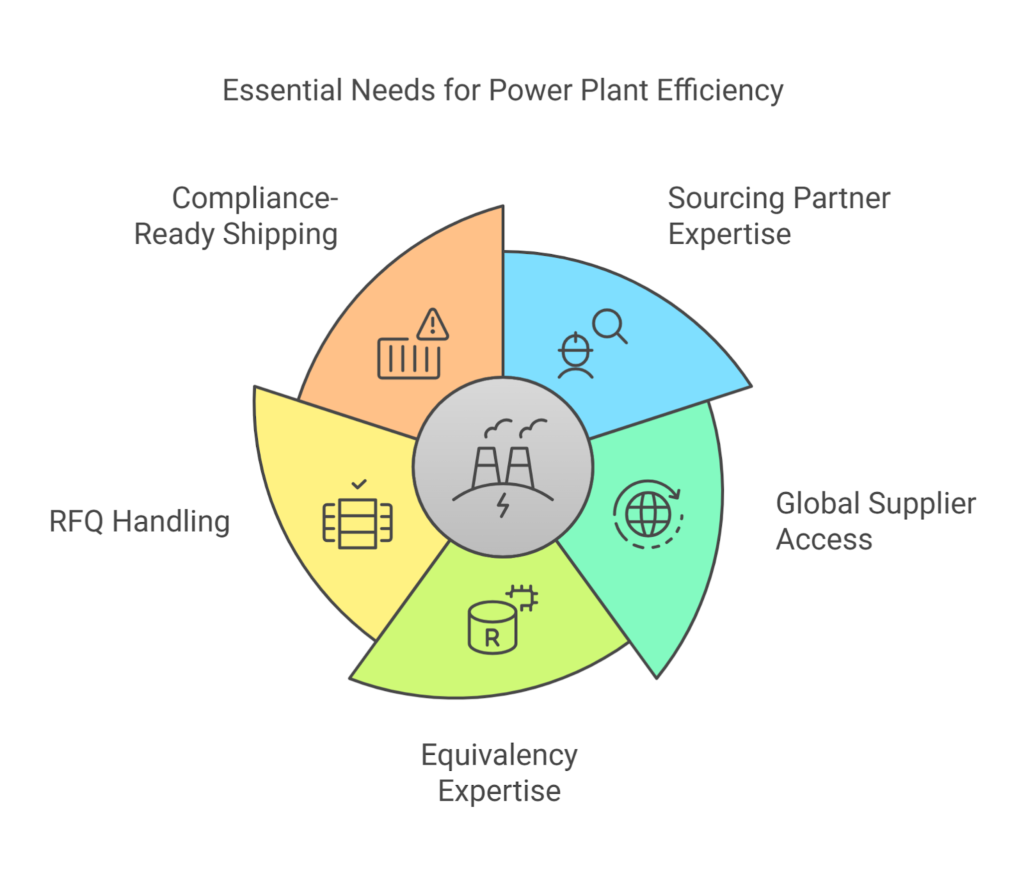

What Power Plant Operators Need Instead

To keep their plants running efficiently, operators need:

- A sourcing partner that understands HRSG internals

- Global supplier access to reduce lead time and cost

- Equivalency expertise to match or replace legacy parts

- Fast and accurate RFQ handling

- Compliance-ready shipping, customs, and paperwork

How ProcureEaze Solves the Problem

ProcureEaze is not a product seller — we’re a solution provider. Here’s what we deliver to power plant operators:

- U.S.-registered sourcing support with a global supply chain

- 24–72 hour RFQ turnaround in most cases

- Technical vetting and drawing reviews

- Pricing from USA, UK, Germany, India, and Asia

- Logistics coordination and import clearance

- Full alignment with your scheduled outage or shutdown window

Use Case: HRSG Burner Tip Sourcing in Texas

One CCPP operator in Texas needed burner tips and diffuser components during an unplanned inspection. The OEM quoted 12 weeks. ProcureEaze delivered an equivalent from the UK in 21 days — with 100% material traceability and at 31% lower cost.

Questions Every Operator Should Ask

- Are you stuck waiting for OEM quotes?

- Do you struggle with price justification for your parts?

- Do your RFQs go unanswered for days or weeks?

- Have you explored sourcing parts from trusted international markets?

- Are your outage schedules at risk due to sourcing issues?

If yes — it’s time to bring a sourcing agent into your procurement plan.

Final Word: HRSG Procurement Doesn’t Have to Be a Problem

Your job is to operate the plant. Our job is to ensure you have the right parts, at the right time, for the right price.

With ProcureEaze, you’re not just buying parts — you’re buying peace of mind.

Let’s simplify your HRSG sourcing — before the next shutdown hits.

Email: cs@procureeaze.com

Phone: (631) 606-6104 – Mr. Saiful Chowdhury

Address: 624 5th Ave, New Hyde Park, NY 11040, USA

Website: www.impro-solution.com

We source globally — USA, UK, EU, Germany, and Asia.